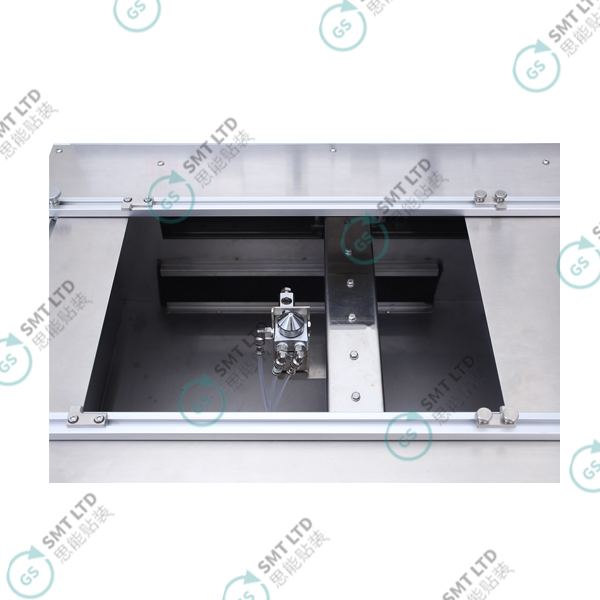

Automatic selective soldering machine

Model:GS301

Working hours:24H

Suitable for: SMT Production Line

Power supply: 3.5 KW

solder groove capacity: 16 KG

Production of solder slag: 0.1 KG

Multilayer PCB Through hole tin penetration rate: 99.99

Production height of PCB: Up:100MM , Down: max 60MM

Application scope: small amount, multiple equipment, High quality welding

- Description

- Inquiry

Product advantages

- The production of tin slag is greatly reduced, and the daily production of tin slag is within 0.1 kg.

- The equipment has low operating power, 3.5KW starting power and 2KW operating power, which can greatly save energy consumption.

- It can basically achieve no cure and greatly reduce the cost of cure.

- Welding yield can be as high as 98% and through-hole tin permeability 99.99%.

- The solder bath is 16KG, and the cost of one-time investment is low.

- The environmental protection rate of production is high, and the amount of smoke is relatively small.

- The amount of flux is very small and the circuit board is clean after welding.

- High quality: Nozzles can be selected according to the size of solder joints, which can control the solder quantity, heat capacity and time of each solder joint. The optimal solder conditions can be set. Large nozzles can be used to improve the efficiency of parts with large demand for heat capacity.

- The equipment occupies less space, is mobile and flexible, and has a high utilization rate.

| Name | Parameter | Notice |

| Platform | PCB Production dimension:250W*330L | X、Y axis import phase stepping motor +THK orIK0 Linear slide rail |

| z axis import servo motorL+ball screw | ||

| solder groove | Solder capacity:16Kg | Electric heating rod:6 pcs |

| *350W | ||

| SUS316 casting groove + | heat-resisting + Anti – solder corrosion Japanese surface treatment technology | |

| SURF Anti-solder Tin corrosion treatment | ||

| N2 preheat unit | preheattemperature:MAX 40CTC | Electric heating ring:1.05KW |

| N2 Purity:>99.99% | ||

| Electrical control unit | single phase 220V 3. 5KW | All electrical component are imported |

| programming software | languages:Chinese and English | Support image,Gerber file,data import |

| scaling powder Nozzle | 0. 5mm | Japan imported Slightly dense second fluid nozzle |

| Dimensions | 830L*630W*1290H(mash welder) | Height of signal lamp is not included |

| 935L*630W*1290H (sprayer) |